Ozzy (2.007 Robot)

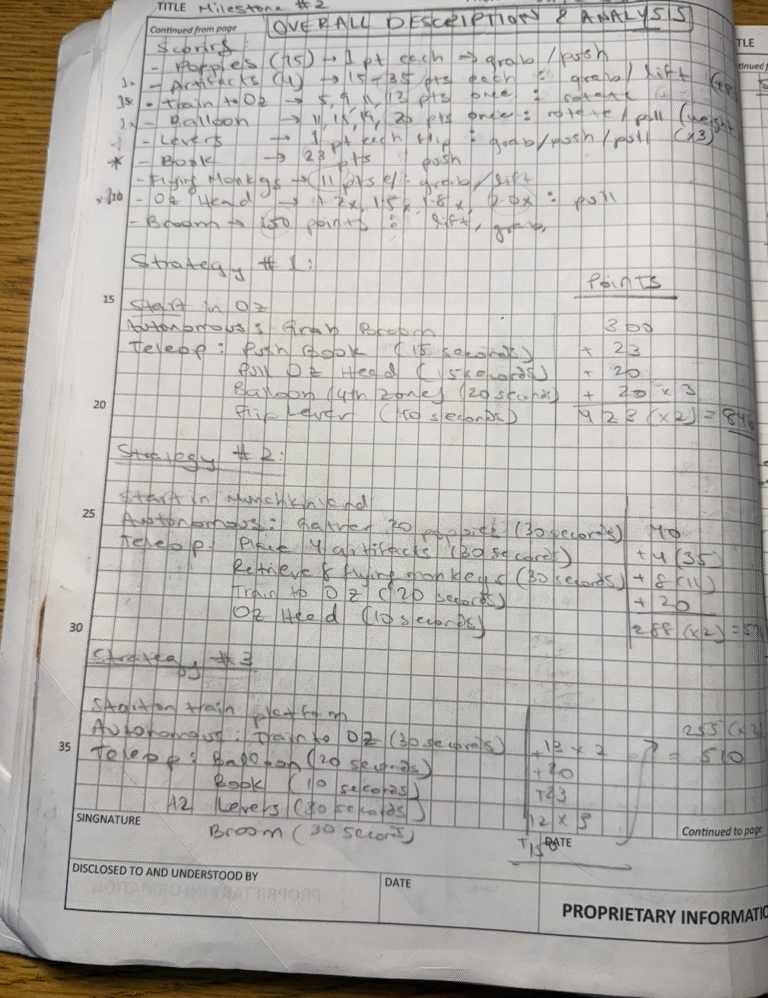

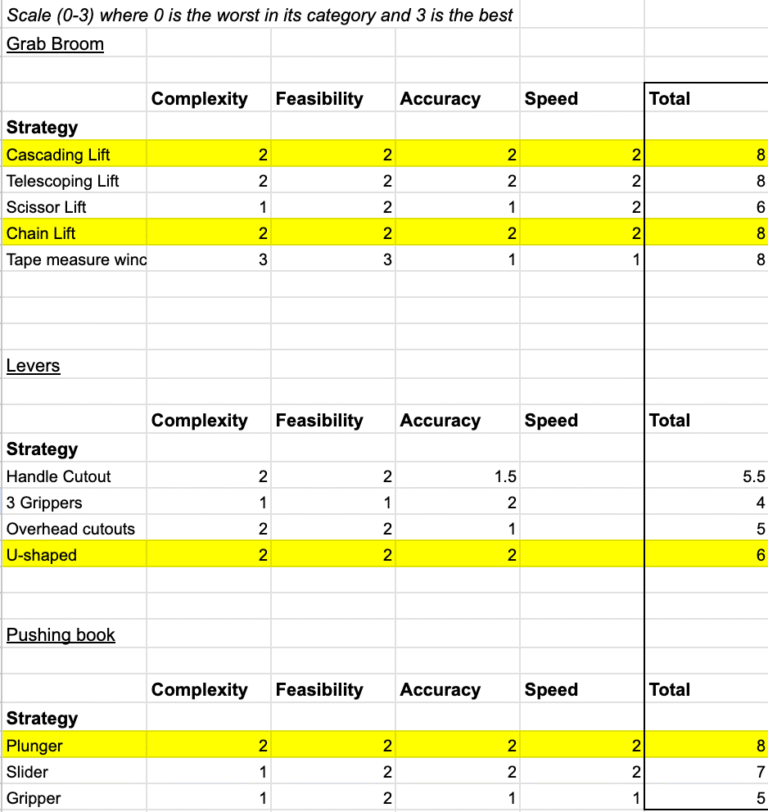

In the spring semester of my sophomore year, I took 2.007, a class where students build robots to compete in a themed competition at the end of the semester. For this year, the theme of the game was based on Wicked, the musical. There were a variety of ways for students to earn points ranging from scooping/pushing poppies to turning gears to ride a train to Oz. I set my sights on one of the most difficult challenges – grabbing the broom above Oz’s head worth 150 points. I thought this task would be an interesting challenge since the broom was around 58″ off the ground, so I began by brainstorming designs. I created a Pugh Chart of different robot designs, considering complexity and points accumulated – I eventually decided to design a continuous linear slide. My strategy involved grabbing the broom then pushing Oz’s head which acted as a pendulum to get a 2x points multiplier, totaling to 300 points!

Objectives

- Able to reach a height of 48″ in under 15 seconds

- Able to push Oz’s head for a 2x multiplier

- Passive claw

- Within 12x12x16″

- Under 10 lb

- Use <= 3 motors

Materials

- 6061 Aluminum stock

- Wheels

- Delrin

- Rope

- Go Builda torque servos

Research

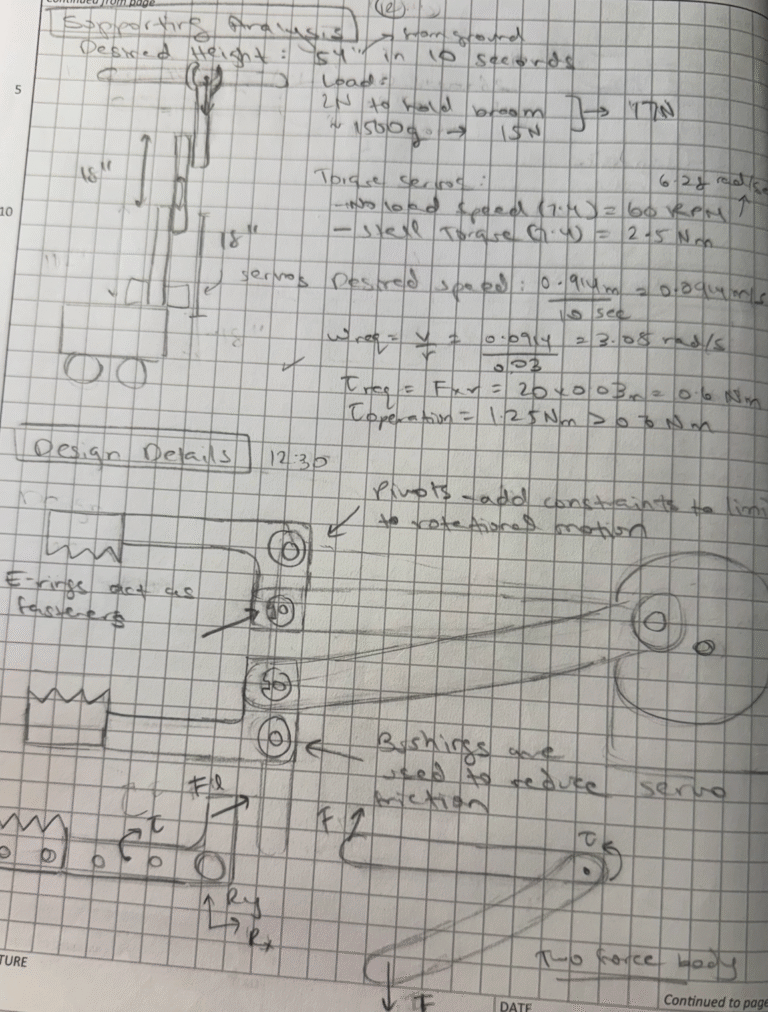

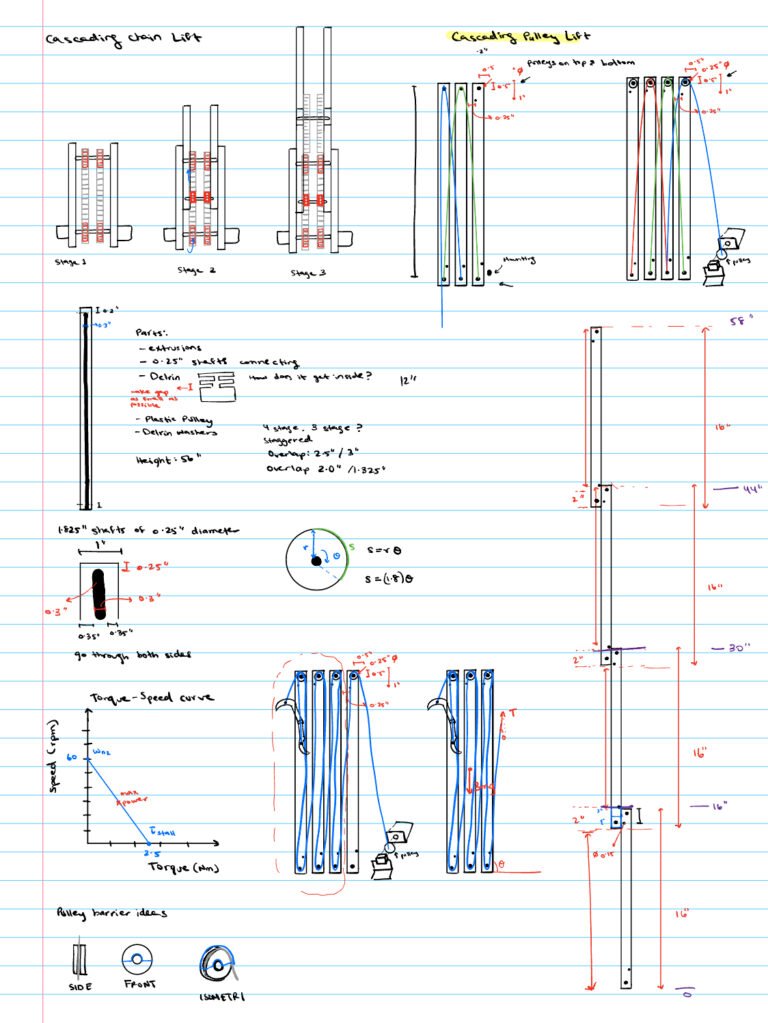

I began brainstorming different mechanisms to grab the broom and chose between three lift options: continuous pulley, cascading pulley and cascading chain. I decided to build the continuous pulley since it was most feasible to complete given the time constraints. It was the most straight forward to manufacture, while having a extension speed on par with the others. It would also be easy to change into a cascading pulley by rearranging the string rigging, allowing me to have flexibility if time permitted. I performed hand calculations to determine whether the torque provided by the motors would be sufficient to power the lift and pull down the broom.

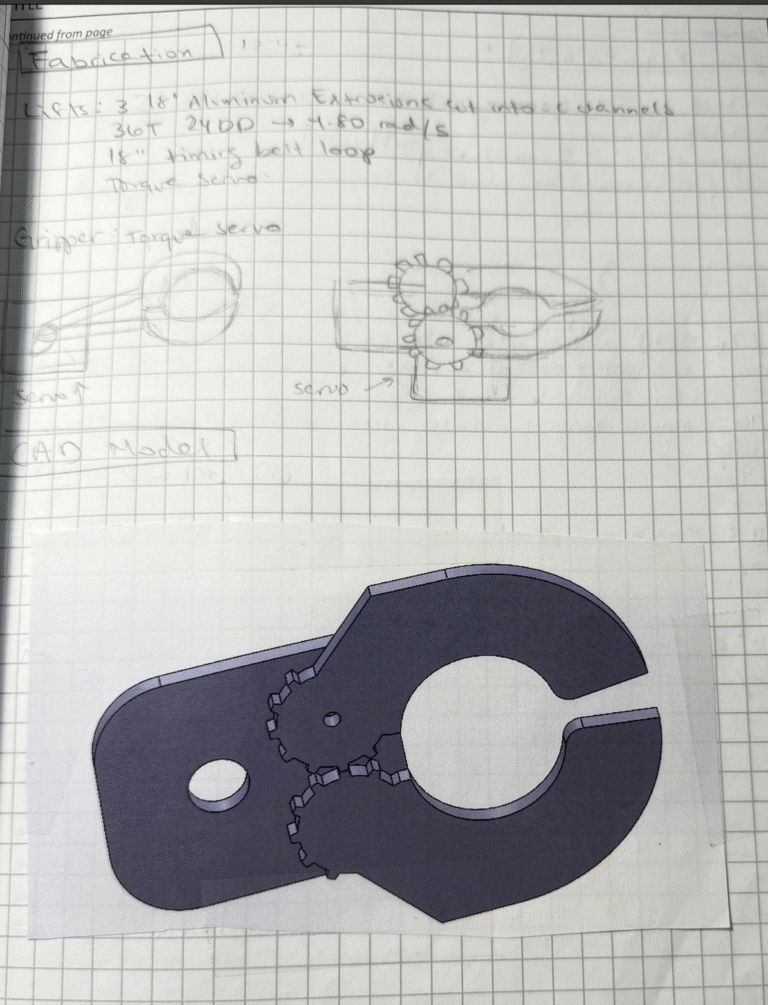

Also, I decided to design a claw that would be able to secure the broom. Ultimately, I decided to move forward with a passive claw design instead that was more simple and minimized the amount of motors used.

Design

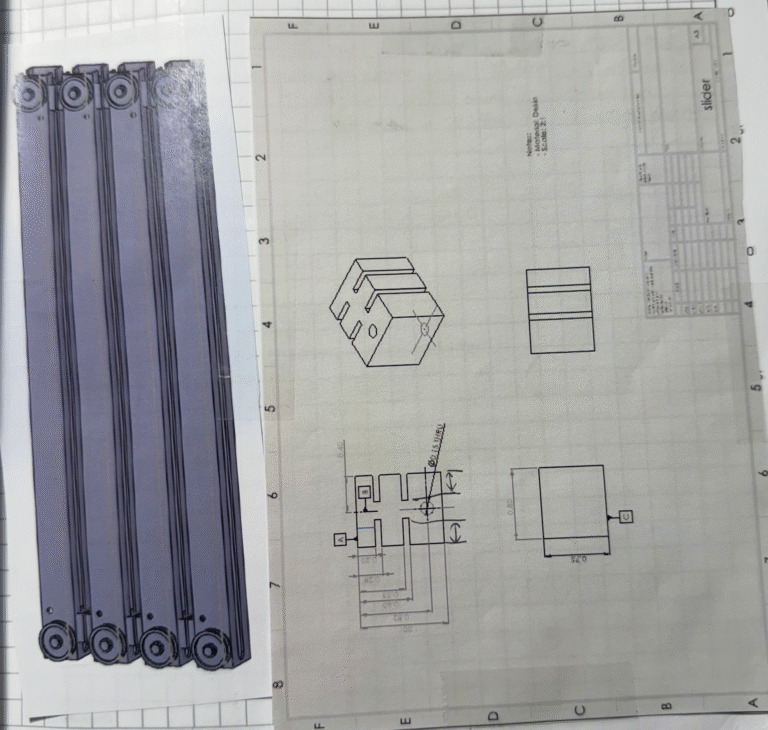

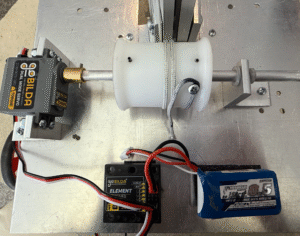

To reach a height of 58″, I designed a 4-stage continuous lift with each slider measuring 16″ and a 2″ overlap. This configuration allowed me to stay within the size constraints while minimizing the number of sliders. Fewer sliders meant faster extension, since additional stages would slow down the lift due to their startup lag. However, this tight fit within the size limit would create challenges later down the road. The linear slides would extend when the string was reeled in by the winch, forcing the extrusions to slide upwards. I tried to maximize the diameter of the winch’s pulley, because the larger it was the more rope was wound up with less rotations, allowing the lift to extend faster. After sketching the robot’s mechanisms, I moved it into SolidWorks to refine the design, iterating as I prototyped different components and discovered what worked and what didn’t. Initially, I planned to create a second claw to pull the hook attached to Oz’s head to pull it, but luckily I realized that my robot was able to push it with its weight unassisted.

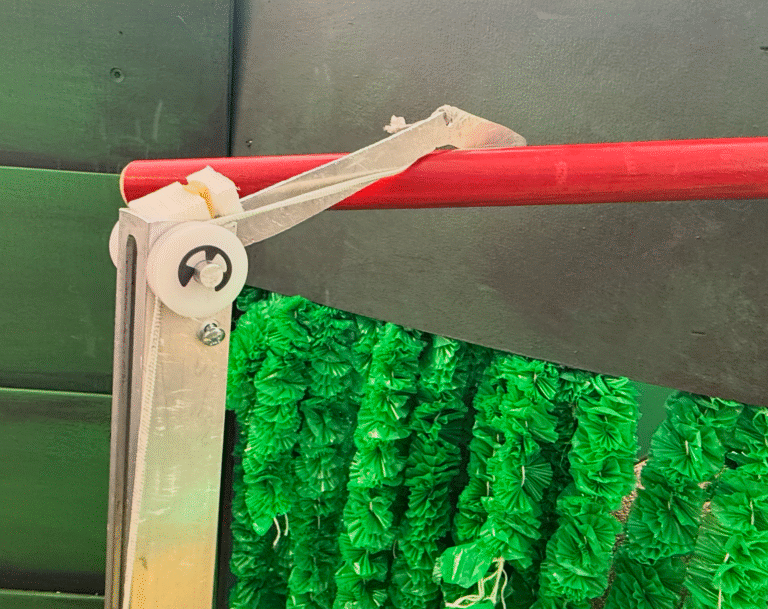

I also decided to create a claw that was passively activated. The claw was tensioned by the string connected to the third and final sliders of the lift, allowing it to only activate once the robot was fully extended. Since this design was more compact than a claw, it addressed the potentially hitting the broom while the lift was extending. I also created engineering drawings of the most critical components.

Build

Over the semester, I honed my machining skills, using the bandsaw to cut the chassis, the lathe to turn the pulleys, and the mill to machine the sliders. A key lesson I learned was the importance of anticipating mismatches in design—had I accounted for them earlier, I could have avoided redrilling misaligned holes multiple times.

I also designed a claw that was passively actuated, since I had already reached the limit on servo motors. To drive the arm, I created a mechanism dependent on the distance between the third and final slider. This ensured the arm would only fully extend when the robot was nearly at maximum height, preventing it from tipping or knocking over the broom too early.

Through testing, I noticed that the string from the pulleys would sometimes fall off, so I 3D printed a cover that helped resolved the issue. Also, I initially used caster wheels on my robot’s chassis, but noticed that this resulted in significant skidding so instead I replaced them with delrin nubs, which allowed for greater maneuverability.

Closer to the competition, I realized my robot was slightly too tall due to the claw mechanism. This led me to frantically grind down the extrusions to fit within the size constraints – something that could have been prevented had I accounted for a greater margin of safety within my design.

Electronics

The electronics for the robot were relatively simple. The battery and servos connected to the receiver, allowing the robot to be controlled through joystick movements. I was interested in exploring using a Teensy to allow the robot to score autonomously, but unfortunately ran out of time to implement it.

Results

I placed in the top 16 of the class! Ozzy was able to successfully reach and grasp the broom within 30 seconds, though with sub par accuracy. Throughout this semester, I was able to learn so much about design principles and manufacturing process. I learned the importance of rapid prototyping and using CAD as a tool to speed up this process.